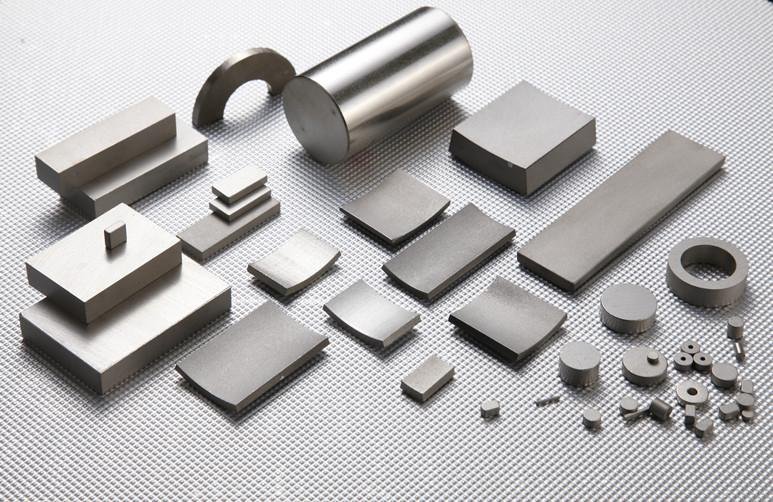

SmCo Magnets

Product Description

|

Physical Characteristics |

|||

|

The physical properties are hard, brittle and fragile, and the accuracy is mainly guaranteed by grinding. The mechanical properties of the surface can be enhanced after plating. |

|||

|

Parameter |

Unit |

SmCo5 |

Sm2Co17 |

|

Density |

G/cm^3 |

8.3 |

8.4 |

|

Curie Temp. |

K |

1000 |

1100 |

|

Vickers hardness |

MPa |

450-500 |

550-600 |

|

Compressive strength |

MPa |

1000 |

800 |

|

Resistivity |

Ω.cm |

5~6X10-5 |

5~6X10-5 |

|

Bending strength |

MPa |

150-180 |

130-150 |

|

Tensile strength |

MPa |

400 |

350 |

|

Coefficient of thermal expansion |

10-6/℃ |

∥6;⊥12 |

∥8;⊥11 |

|

Chemical properties |

|||

|

Chemical properties are stable, not easy to be oxidized and corroded. Generally, surface treatment is not required. Sometimes, surface plating is used to enhance the mechanical properties of products, such as zinc plating, nickel plating, tin plating, etc |

|||

|

Temperature characteristic |

|||

|

With good temperature stability, the maximum working temperature can reach 350℃ |

|||

|

Performance & Grade |

||||||||||||

|

Grade |

Br |

Hcb |

Hcj |

BH(max) |

Curie Temp. TC |

Maxmimum Working Temp. TW |

Temp. Coefficient of Br |

|||||

|

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/M3 |

MGOe |

℃ |

℃ |

%/℃ |

|

|

(SmPr)Co5 |

YX-18 |

0.85-0.90 |

8.5-9.0 |

660-700 |

8.3-8.8 |

1194-1830 |

15-23 |

127-143 |

16-18 |

750 |

250 |

-0.050 |

|

YX-20 |

0.90-0.94 |

9.0-9.4 |

676-725 |

8.5-9.1 |

1194-1830 |

15-23 |

150-167 |

19-21 |

750 |

250 |

-0.050 |

|

|

YX-22 |

0.92-0.96 |

9.2-9.6 |

710-748 |

8.9-9.4 |

1194-1830 |

15-23 |

160-175 |

20-22 |

750 |

250 |

-0.050 |

|

|

YX-24 |

0.96-1.00 |

9.6-10.0 |

730-770 |

9.2-9.7 |

1194-1830 |

15-23 |

175-190 |

22-24 |

750 |

250 |

-0.050 |

|

|

SmCo5 |

YX-18S |

0.84-0.89 |

8.4-8.9 |

660-700 |

8.3-8.8 |

≧1830 |

≧23 |

135-151 |

17-19 |

750 |

250 |

-0.035 |

|

YX-20S |

0.89-0.93 |

8.9-9.3 |

684-732 |

8.6-9.2 |

≧1830 |

≧23 |

150-167 |

19-21 |

750 |

250 |

-0.040 |

|

|

YX-22S |

0.92-0.96 |

9.2-9.6 |

710-756 |

8.9-9.5 |

≧1830 |

≧23 |

167-183 |

21-23 |

750 |

250 |

-0.045 |

|

|

YX-24S |

0.96-1.00 |

9.6-10.0 |

740-788 |

9.3-9.9 |

≧1830 |

≧23 |

183-199 |

23-25 |

750 |

250 |

-0.045 |

|

|

Sm2Co17 |

YXG-22 |

0.93-0.97 |

9.3-9.7 |

676-740 |

8.5-9.3 |

≧1433 |

≧18 |

160-183 |

20-23 |

800 |

300 |

-0.020 |

|

YXG-24 |

0.95-1.02 |

9.5-10.2 |

692-764 |

8.7-9.6 |

≧1433 |

≧18 |

175-191 |

22-24 |

800 |

300 |

-0.025 |

|

|

YXG-26 |

1.02-1.05 |

10.2-10.5 |

748-796 |

9.4-10.0 |

≧1433 |

≧18 |

191-207 |

24-26 |

800 |

300 |

-0.030 |

|

|

YXG-28 |

1.03-1.08 |

10.3-10.8 |

756-812 |

9.5-10.2 |

≧1433 |

≧18 |

207-220 |

26-28 |

800 |

300 |

-0.035 |

|

|

YXG-30 |

1.08-1.10 |

10.8-11.0 |

788-835 |

9.9-10.5 |

≧1433 |

≧18 |

220-240 |

28-30 |

800 |

300 |

-0.035 |

|

|

YXG-32 |

1.10-1.13 |

11.0-11.3 |

812-860 |

10.2-10.8 |

≧1433 |

≧18 |

230-255 |

30-32 |

800 |

300 |

-0.035 |

|

|

YXG-24H |

0.95-1.02 |

9.5-10.2 |

692-764 |

8.7-9.6 |

≧1990 |

≧25 |

175-191 |

22-24 |

800 |

350 |

-0.025 |

|

|

YXG-26H |

1.02-1.05 |

10.2-10.5 |

748-796 |

9.4-10.0 |

≧1990 |

≧25 |

191-207 |

24-26 |

800 |

350 |

-0.030 |

|

|

YXG-28H |

1.03-1.08 |

10.3-10.8 |

756-812 |

9.5-10.2 |

≧1990 |

≧25 |

207-220 |

26-28 |

800 |

350 |

-0.035 |

|

|

YXG-30H |

1.08-1.10 |

10.8-11.0 |

788-835 |

9.9-10.5 |

≧1990 |

≧25 |

220-240 |

28-30 |

800 |

350 |

-0.035 |

|

|

YXG-32H |

1.10-1.13 |

11.0-11.3 |

812-860 |

10.2-10.8 |

≧1990 |

≧25 |

230-255 |

30-32 |

800 |

350 |

-0.035 |

|